Staged Anaerobic Digestion

Staged anaerobic digestions usually with two or more reactors in series, are designed to optimize the process and enhance gas production.

In a single stage anaerobic digestion, all the anaerobic process reactions take place inside a single reactor. The operating conditions are more or less suitable for all the reactions and no particular phase has been optimized. Single stage anaerobic digestion requires less capital cost, less maintenance but has lower gas production and organic conversion rate.

In a multi-stage anaerobic digestion, multiple reactors (usually two of them) are designed in series to optimize the process and enhance gas production. By introducing physical separation or staged operation, facilities can optimize each process reaction for the breakdown of the organics and enhance more organic destruction. Although multi-stage or staged anaerobic digestion process is more complex and require more capital cost, some of the benefits of this system as reported (EPA, 2006) are as follows:

- Enhance gas production

- More volume reduction through VS destruction

- Higher quality biosolid (Class A biosolid can be achieved by incorporating a thermophilic stage)

- Better odour control

- Can configure to reduce foaming problem

- Short circuit prevention via multiple reactors, each with optimized retention time.

Different Configuration of Staged Anaerobic Digestion

Different types of staged anaerobic digestion (EPA, 2006; Metcalf and Eddy, 2003) and their configurations are listed and discussed as follows:

- Staged Mesophilic Digestion

- Acid/Gas (AG) Phased Digestion

- Temperature Phased Anaerobic Digestion (TPAD)

- Staged Thermophilic Digestion

Staged Mesophilic Digestion

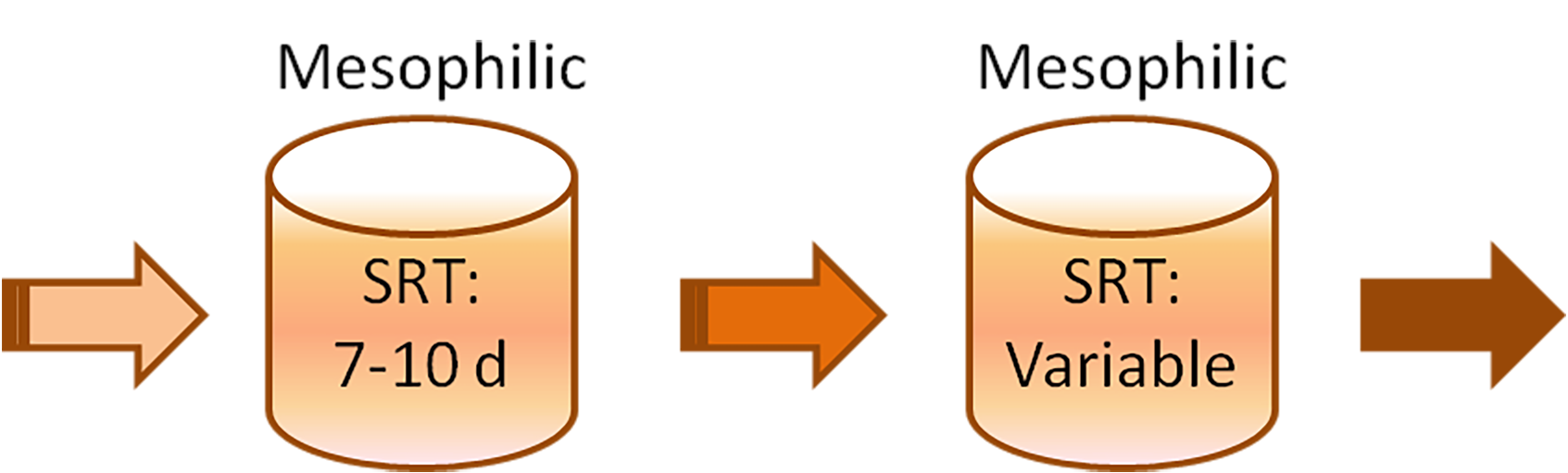

Two anaerobic digesters coupled in series as primary and secondary digester is not uncommon, but there is not much information available regarding two heated well mixed digester in series. Literature findings indicated that two staged mesophilic digestion may produce more stable, less odorous biosolids that are easier for dewatering (Metcalf and Eddy, 2003).

A Staged

Mesophilic Digestion Configuration

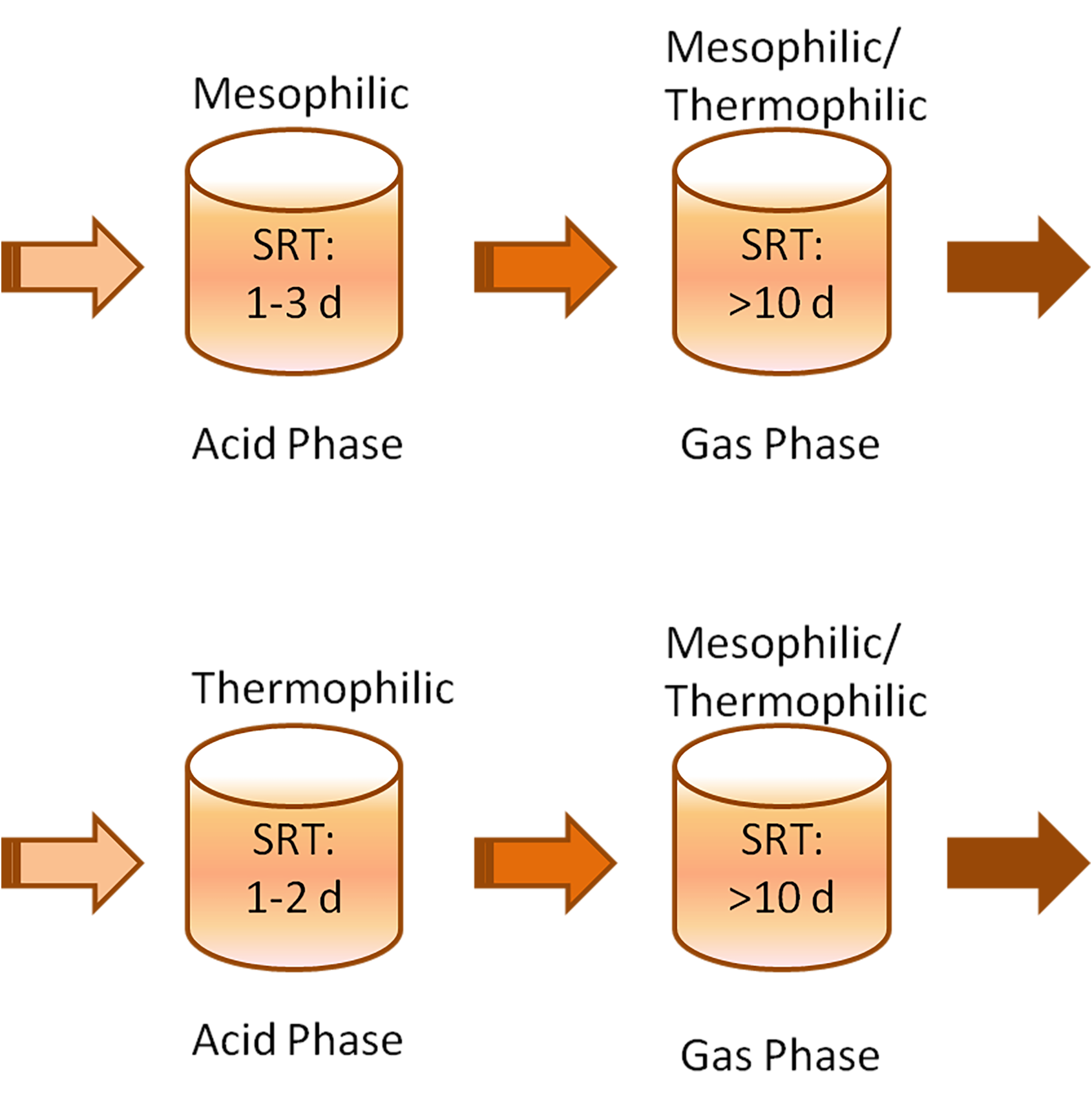

Acid/Gas (AG) Phased Digestion

In a two-stage acid/gas (AG)-phased digestion, the acid-forming stage (hydrolysis and volatile acid fermentation) are physically separated from the methane gas-forming stage by dedicating a digester designed and optimized for each of these two stages. The first digester is commonly known as primary or acid phase digester. The first phase is conducted at an acidic pH (pH 6 or less) and at a lower SRT favorable for volatile acid formation. In the second stage digester, usually known as secondary digester, methanogenic bacteria convert the acids and soluble organics into methane rich biogas. The second digester is operated at a neutral pH and longer SRT to suit the need of methanogenic bacteria and maximize gas production (Metcalf and Eddy, 2003). In a typical two stage AG system, primary digester is usually heated to optimize the hydrolysis and acid forming reaction, while the secondary digester is not because of the exothermic (heat-producing) nature of the methane formation reaction (EPA, 2006). Some advantages and disadvantages of the AG process, as listed in the WEF white paper on the anaerobic digestion (2004) are:

Advantages:

- Greater volatile solids destruction in a smaller volume than a conventional mesophilic digestion process

- A reduction in digested solids processing and handling

- Foam control

- Increased gas production and stability

- Class A potential with a thermophilic reactor operation (AG-MT/AG-TM)

Disadvantages:

- Increased

complexity from multiple phases

Two

Acid/Gas (AG) Phased Digestion Configurations

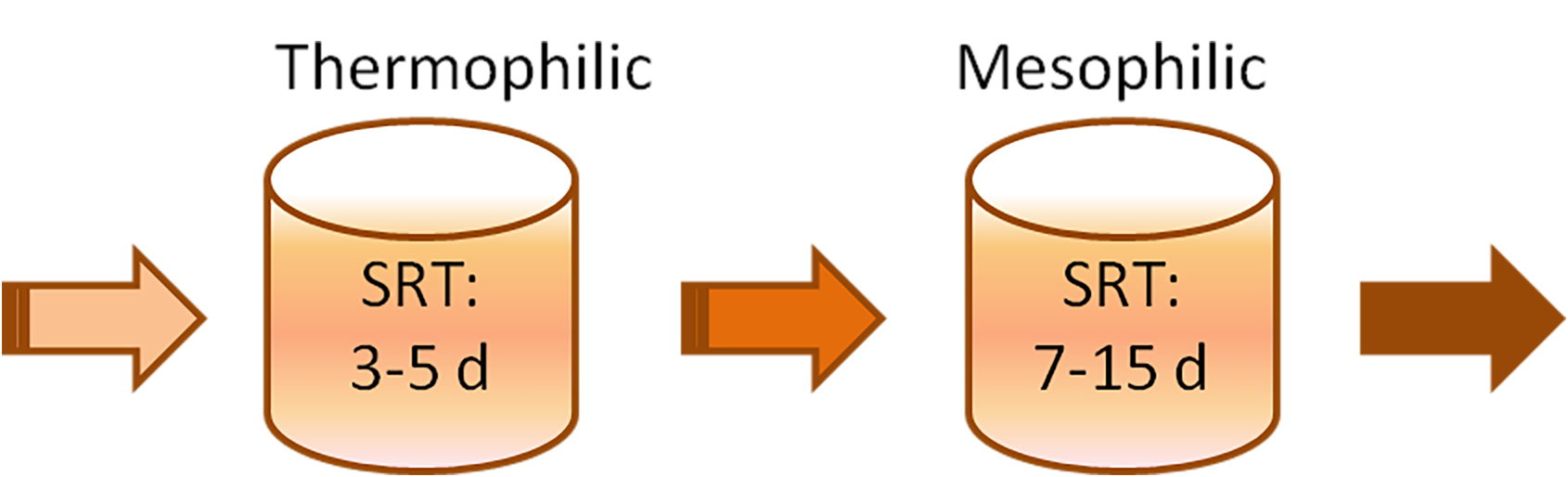

Temperature Phased Anaerobic Digestion (TPAD)

The Temperature Phased Anaerobic Digestion (TPAD) incorporates both thermophilic and mesophilic reactors connected in series to take advantage of the higher digestion rate of thermophilic digestion as well as the higher stability of the mesophilic digestion. The thermophilic digestion rate is usually four times faster than the mesophilic digestion (Metcalf and Eddy, 2003). On the other hand, adding a mesophilic digestion at the end not only improved stability of the digestion operation but also destroyed odorous compounds produced during the thermophilic stage. Overall the TPAD process has greater volatile suspended solids (VSS) destruction and gas production ability. It is reported that the VSS destruction efficiencies of the TPAD process are 15-25% greater than the single stage mesophilic digestion process. The TPAD process is also reported to have better shock absorbing capacity, lesser foaming issues and the ability to produce a ‘Class A’ biosolids (Metcalf and Eddy, 2003).

A Temperature Phased Anaerobic Digestion (TPAD)

Configuration

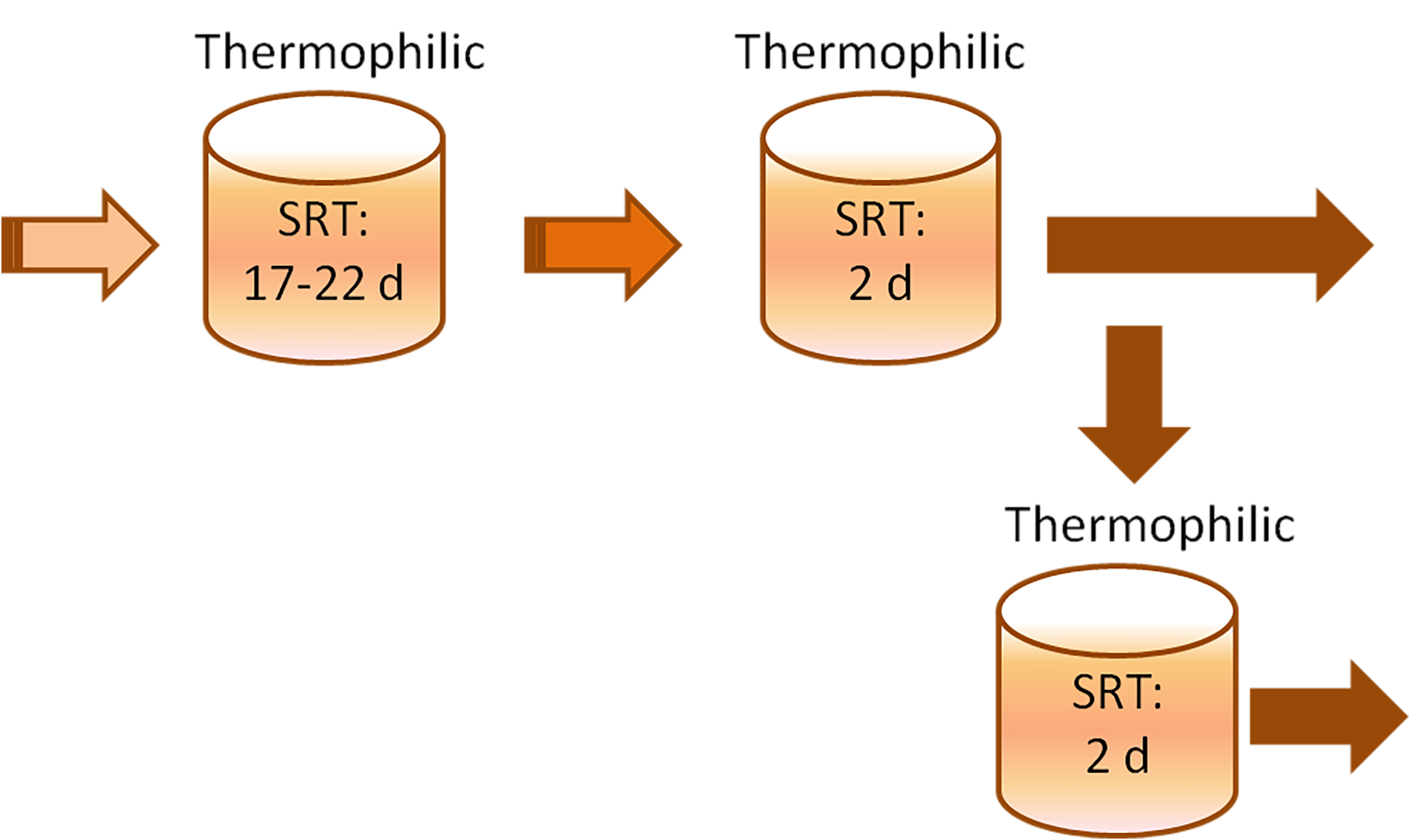

Staged Thermophilic Digestion

In staged thermophilic digestion, a large digester is followed by one or more smaller digester to prevent pathogen short circuiting and achieve a Class A biosolid. One such example is Annacis Island Wastewater Treatment Plant in Vancouver BC, Canada; where first stage is followed by three subsequent stages (Metcalf and Eddy, 2003).

A Staged Thermophilic Digestion Configuration

DD

Discover more on Staged Anaerobic Digestion!

Go back to the Anaerobic Digestion Types!

Go Back to the Eco Ambassador Home!

Total Visits to Site: