Anaerobic Digestion Pre-treatments

Over the recent years, options for anaerobic digestion feedstocks have increased and widen, especially with the introduction of waste to energy concept. Different wastes or feedstocks types required different pre-treatment or pre-treatment series based on their characteristics. Selection of pre-treatment plays a very significant role in the process; because not only the overall process train and process efficiency but also the final process outcomes and economics are dependent on that.

In general, the feed pre-treatment technologies are focused on achieving the following objectives:

- Removing toxic, inhibitory and unwanted substance for digester

- Reducing digester maintenance and clean up

- Homogenizing the feedstock mixture

- Adjusting moisture content, temperature etc. of the feed for digestion process

- Enhancing biogas production from the digester

- Promoting higher organic and volatile solid destruction inside the digester

- Reducing feedstocks volume and increasing in digester capacity

- Increasing hygienic safety and removing high pathogen from feedstocks

- Decreasing processing and disposal cost of the end products

Potential Feedstocks Without Pre-treatments

Anaerobic Digestion Pre-treatment Categories

In general, the type and level of pre-treatment mainly depends on the purity and characteristics of the feedstocks.

Commonly, the first step of any pre-treatment process is to sort out and remove the non-biodegradable and inert contaminants from the feedstocks such as grit, sand, stones, metal pieces, paper or plastic packaging etc. These contaminants, If not removed, can cause damage to the downstream processes and equipments; for example excessive grit and sand can settle in the digester bottom, clog pipes and damage process valves and sensors.

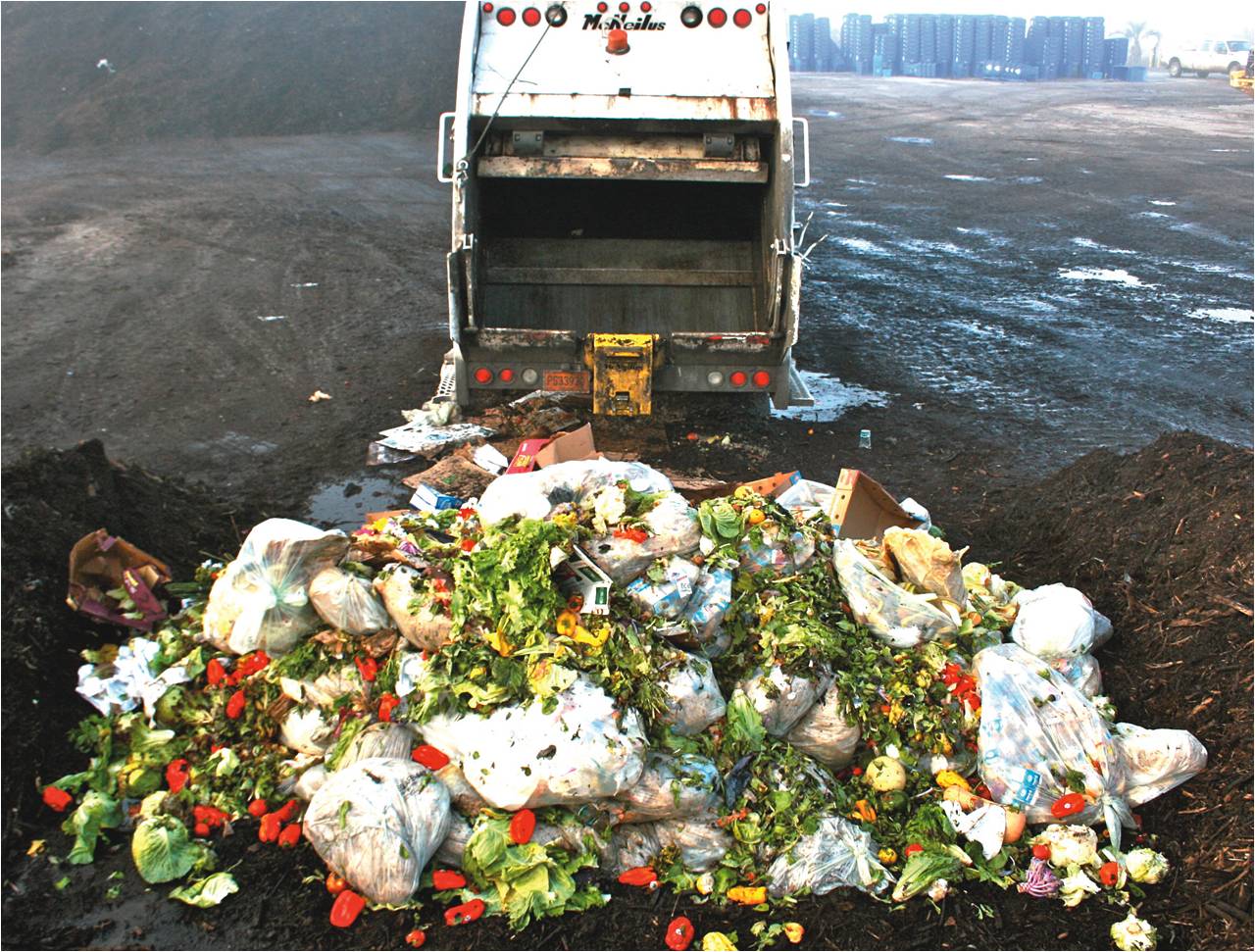

Hygienic considerations become essential when the feed steam may contain harmful microorganisms and pathogens depending on their origin and condition - such feed stokes are slaughterhouse wastes; other animal wastes like slurry from chicken, pigs and cattle farms; food wastes and wastewater sludge.

Some feedstocks, like wastewater sludge or waste rich in ligno-cellulosic component, need pre-treatment for further process enhancement and higher energy recovery. Pre-treatments expose and increase the surface area of these feedstocks by breaking them down further and thus increasing the organic loading rates and reducing the required retention time in the digester.

So, pre-treatment can be generally divided into the following three categories:

The first step of pre-treatment for any contaminated feedstocks is to remove non-biodegradable and inert materials that can negatively affect downstream processes and equipment- Read More.Any feedstock that contains pathogens or infectious microorganisms need to go through some level of pre-treatment for hygienisation, sterilization or pasteurization based on the degree of contamination -Read More.

It is widely stated that hydrolysis is one of the rate limiting steps for anaerobic digestion especially in the presence of complex organic compounds in the feedstocks- Read More.Discover more on Food Waste Pre-treatment

Go back to the Eco Ambassador Home

Discover more on Anaerobic Digestion Pre-treatment

Total Visits to Site: