Optimizing Wastewater Aeration System

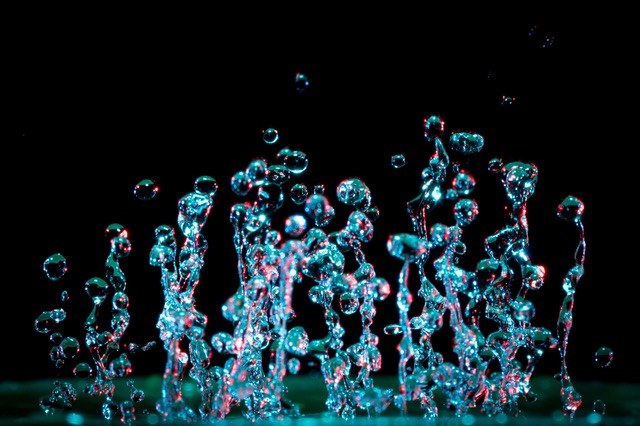

Wastewater

aeration is the process of supplying oxygen in the form of air into the wastewater

microorganisms to facilitate or break-down the waste products. It is a critical

process as without enough oxygen there will be incomplete degradation of the

pollutants resulting inefficient treatment. So, an optimize aeration system is

essential for wastewater treatment plants. But wastewater aeration process is also

the most energy intensive phase for aerobic biological wastewater treatment plants.

Usually aeration consumes between 25 to 60 percent of the total energy used in

a municipal the wastewater treatment plant (USEPA). With rising energy cost and

scarcity, optimizing the aeration process has become even more crucial to check

the operating cost.

Wastewater Aeration System Optimizing Strategies:

In order to optimize the aeration process, we need to focus on its individual component. In general, the aeration system can be improved or optimized by focusing on the following three areas:

- Diffuser technology and its configuration

- Blower technology and configuration

- Dissolve oxygen monitoring and control technologies

Energy Reduction and Recovery in Wastewater Treatment Plants!

Towards Energy Neutral/Energy Positive Status - Online Course!

Diffuser technology and its configuration:

Changes in number of diffusers and diffuser configuration can lead to increased energy efficiency. A common approach is to use tapered aeration to reduce the rate of oxygen supply along the length of a basin (WEF and ASCE 2010); that is placing more diffusers at the inlet to the basin where the organic loading is highest and decreasing the number of the diffusers along the basin’s length. Tapered aeration better matches the oxygen demand across the basin by supplying more air to the head of the basin where it is needed and less air near the end of the basin where the food‐to‐microorganisms (F/M) ratio is lower. This approach thereby saves significant energy.

Also, using fine bubble diffusers provides significant reductions in

aeration energy consumption over mechanical and coarse bubble aeration. There

is an increased oxygen transfer rates afforded by the high surface area of the

fine bubbles.

Blower technology and configuration:

Many plants have more capacity in their aeration system than needed because the population growth projected during the design phase. These applications, can often be more efficiently served by a smaller blower. There are many blower configurations that can operate efficiently, especially in larger plants. For example, replacing larger blowers with one or more smaller units or installing variable frequency drives (VFDs). Water Environment Federation (2009) reports that VFD operation of multi‐stage centrifugal blowers is 15 to 20 percent more efficient than throttling. In addition, US EPA (2010) has identified High‐Speed Gearless, or “Turbo,” blowers as a significant energy savings technology for the wastewater industry.

Dissolve oxygen monitoring and control technologies:

Earlier Dissolve oxygen (DO) measurement in an aeration tank of wastewater treatment plant was manual. It was done once or few times a day and aeration modification was made based on that with a high safety factor. But now with an advanced automated dissolved oxygen monitoring and control technology, it is possible to maintain the dissolved oxygen (DO) level of the aeration tank(s) at a pre-set control point by varying the air flow rate to the aeration system. Because energy required increases exponentially as the DO concentration in the aeration tank increases, energy savings from automated DO control can be significant.

Know more about wastewater aeration Optimization here!

Know about wastewater pump system Optimization here!

Know about energy efficient wastewater treatment!

Go back to The EcoAmbassador Home!

Total Visits to Site: